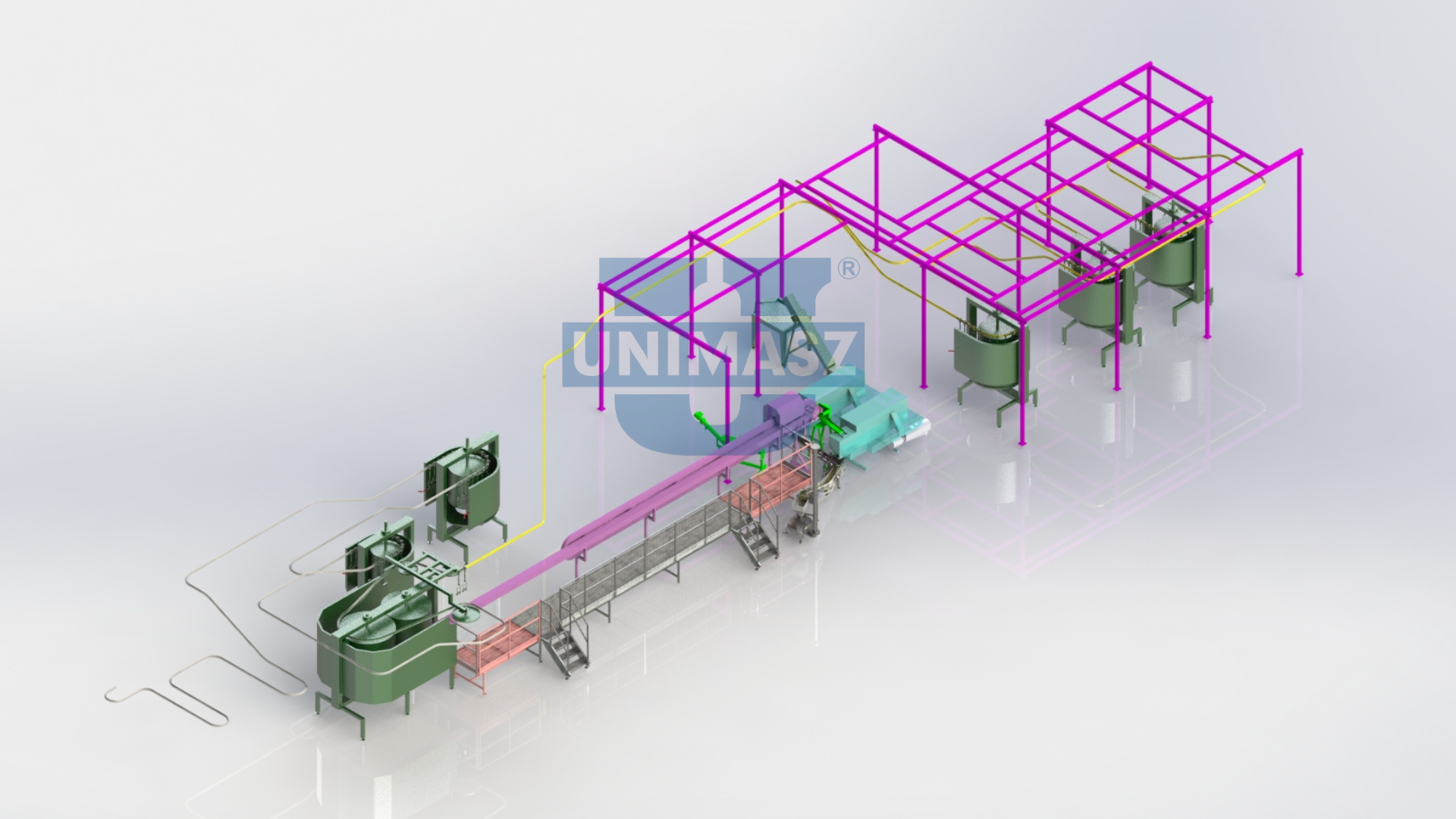

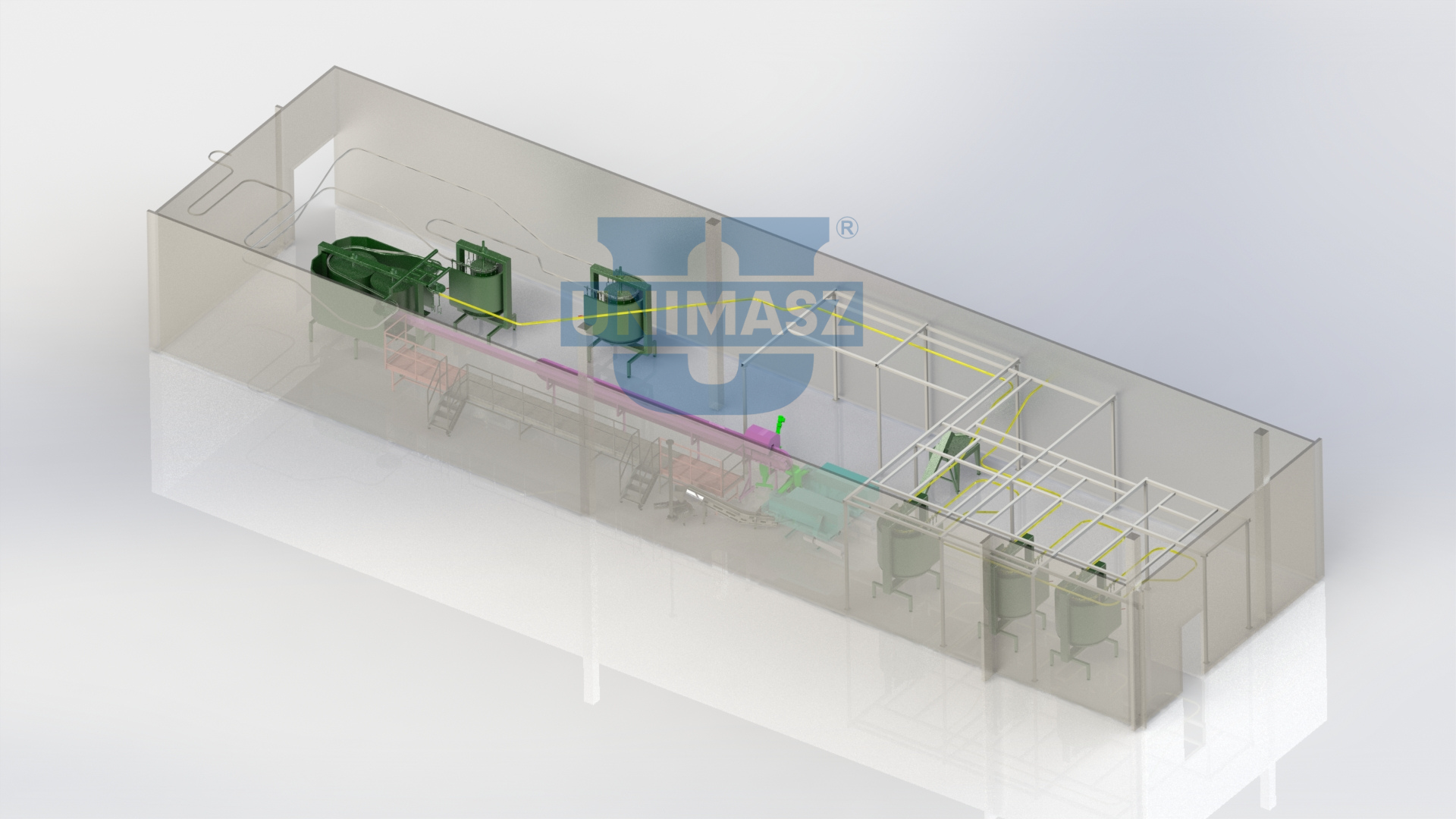

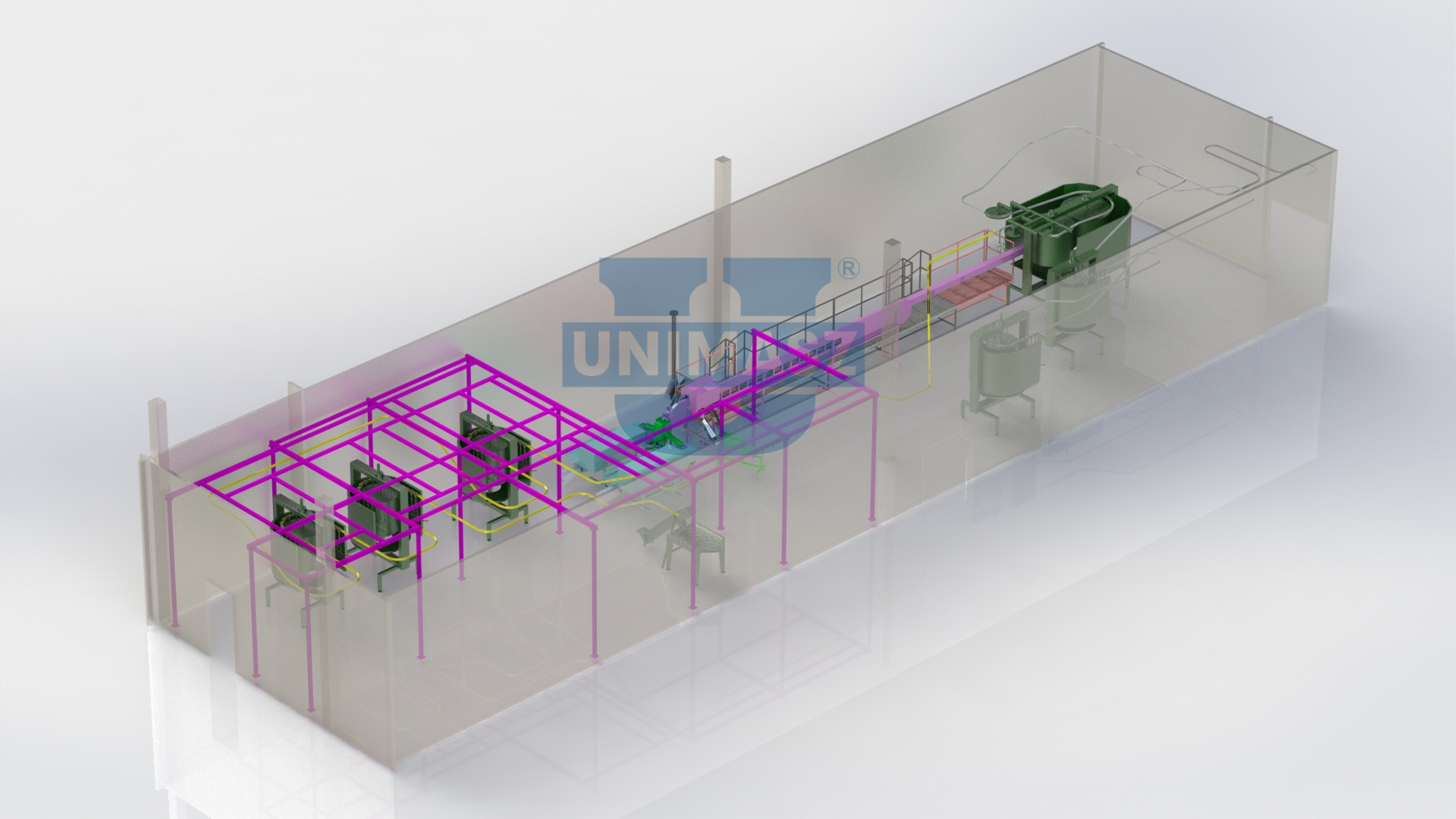

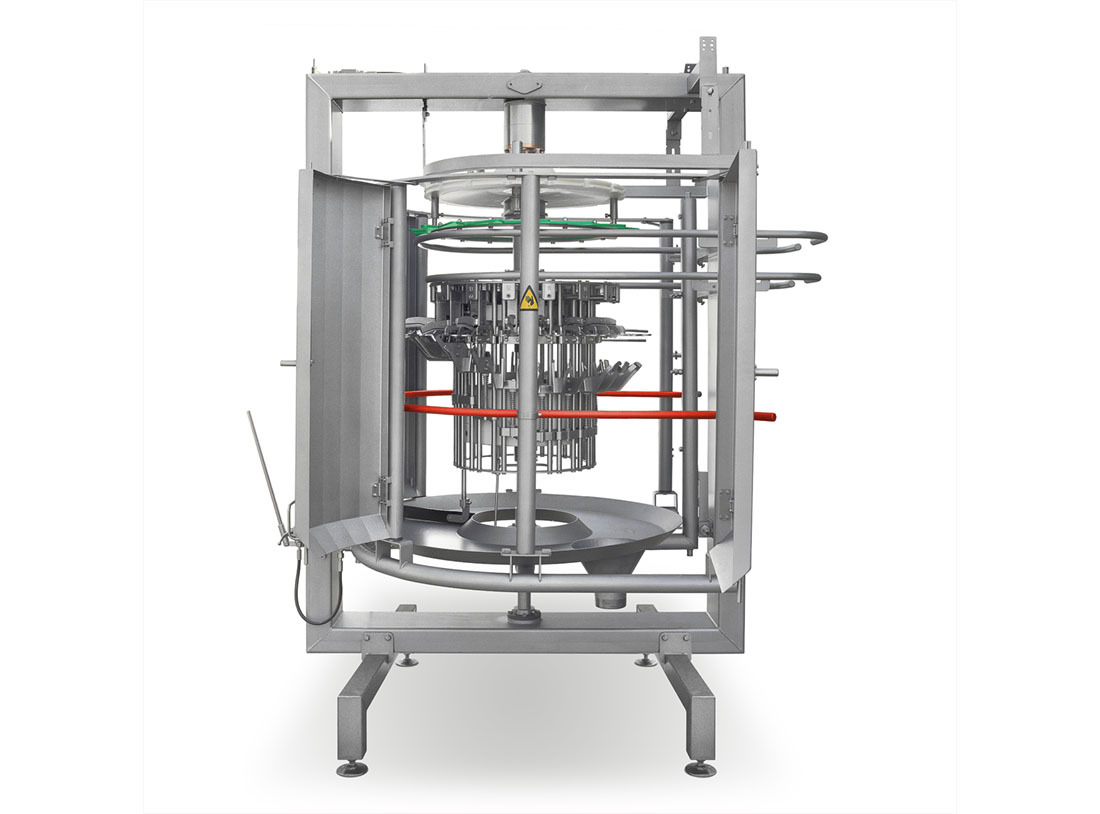

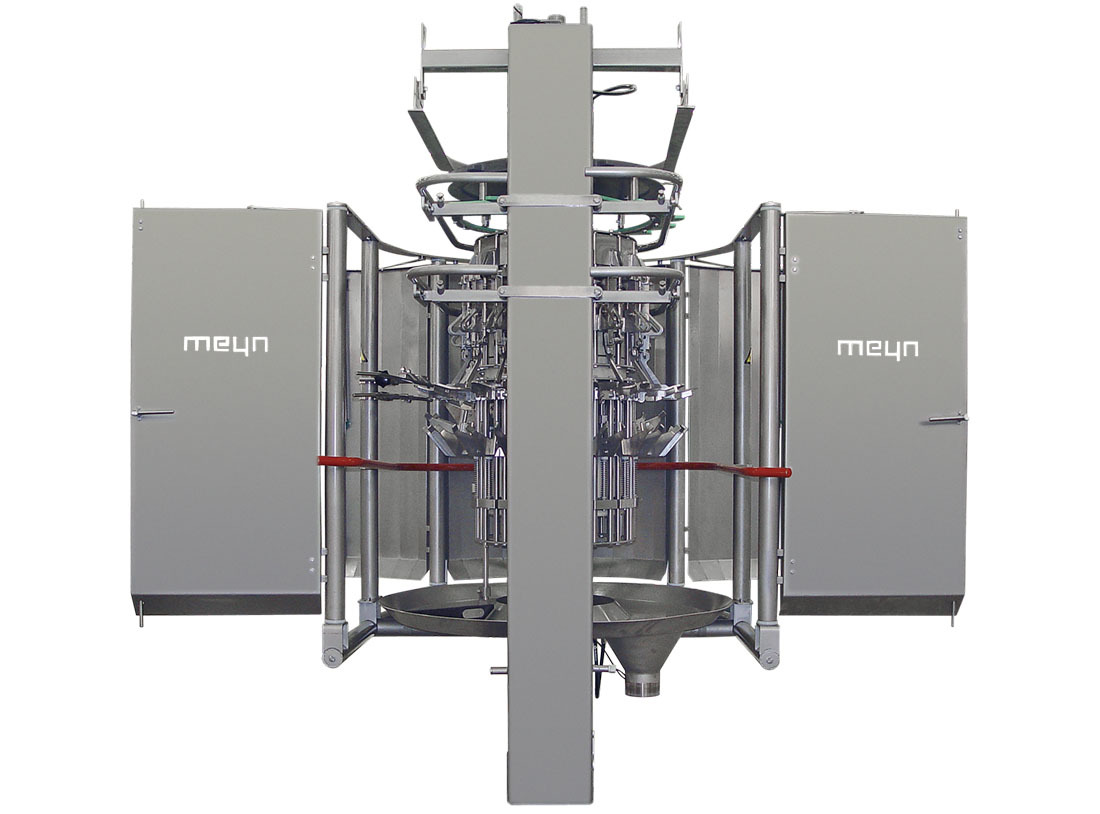

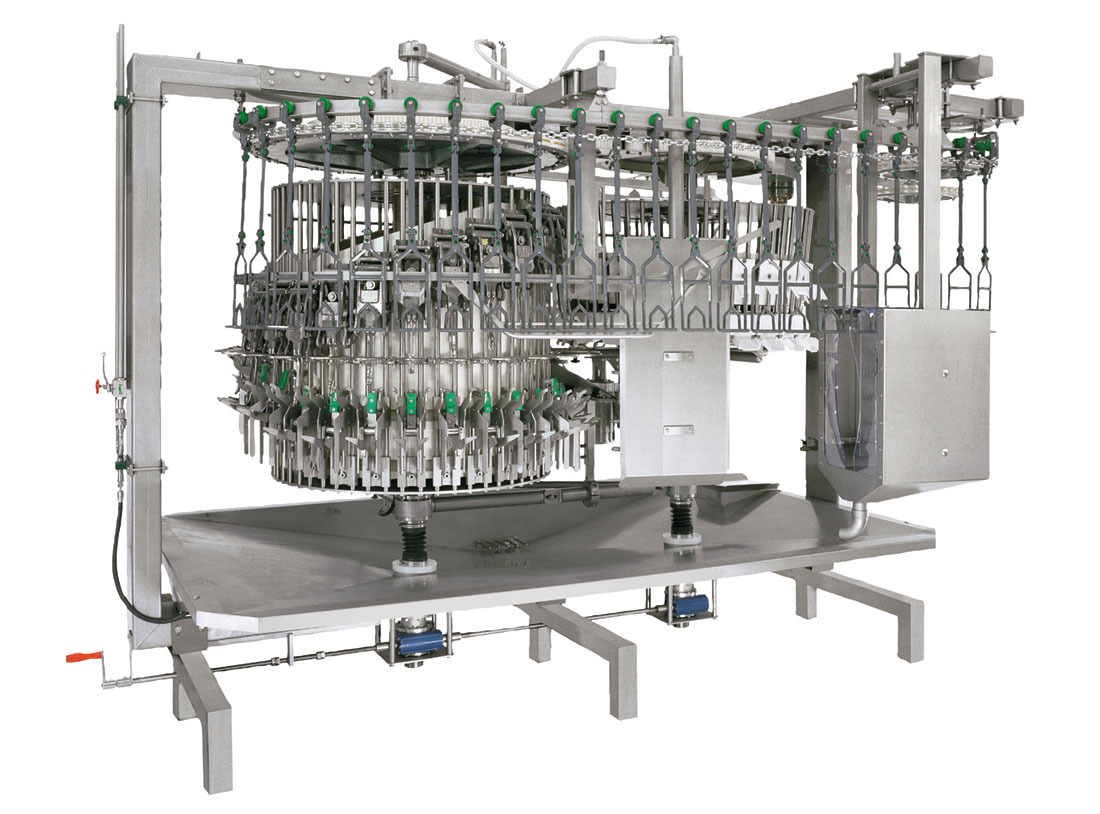

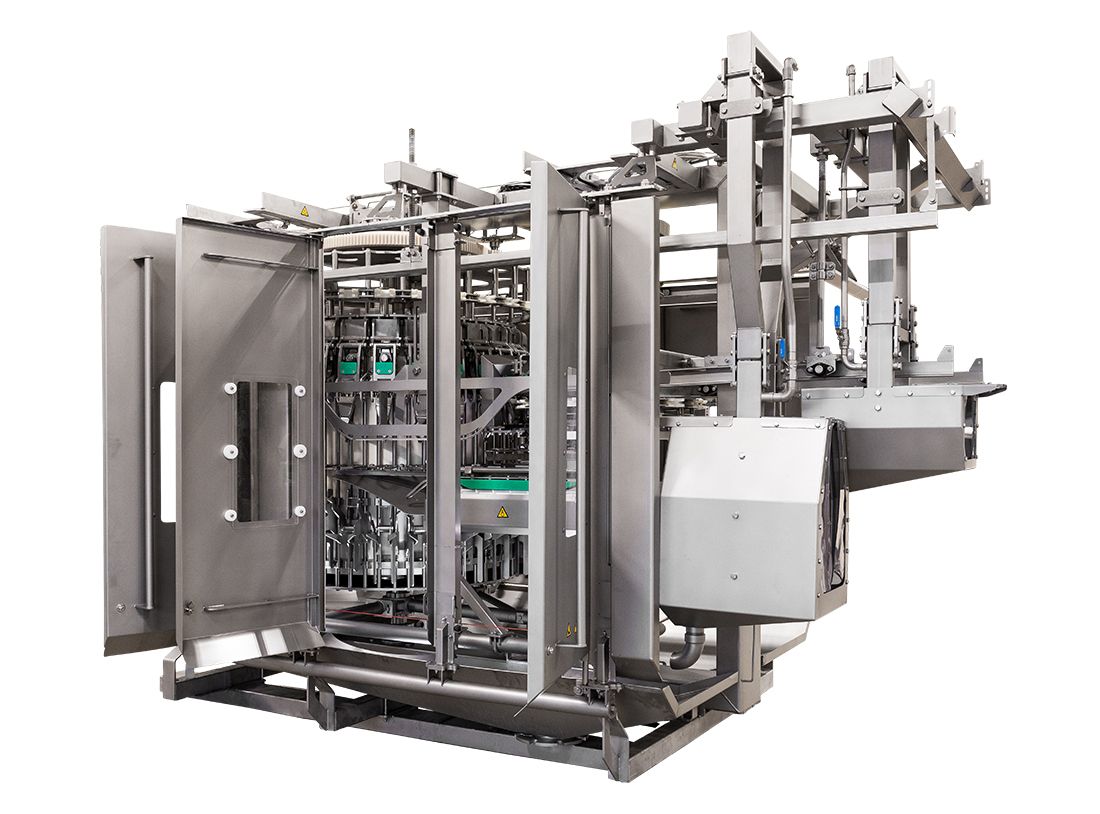

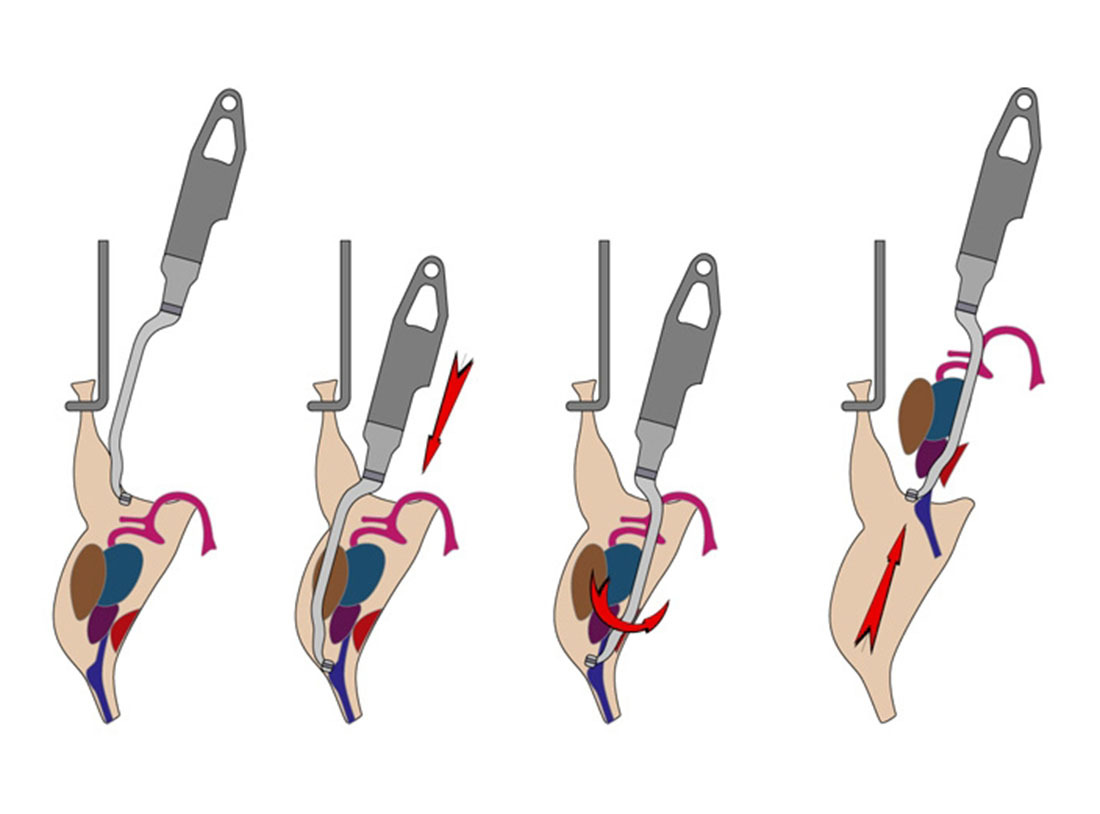

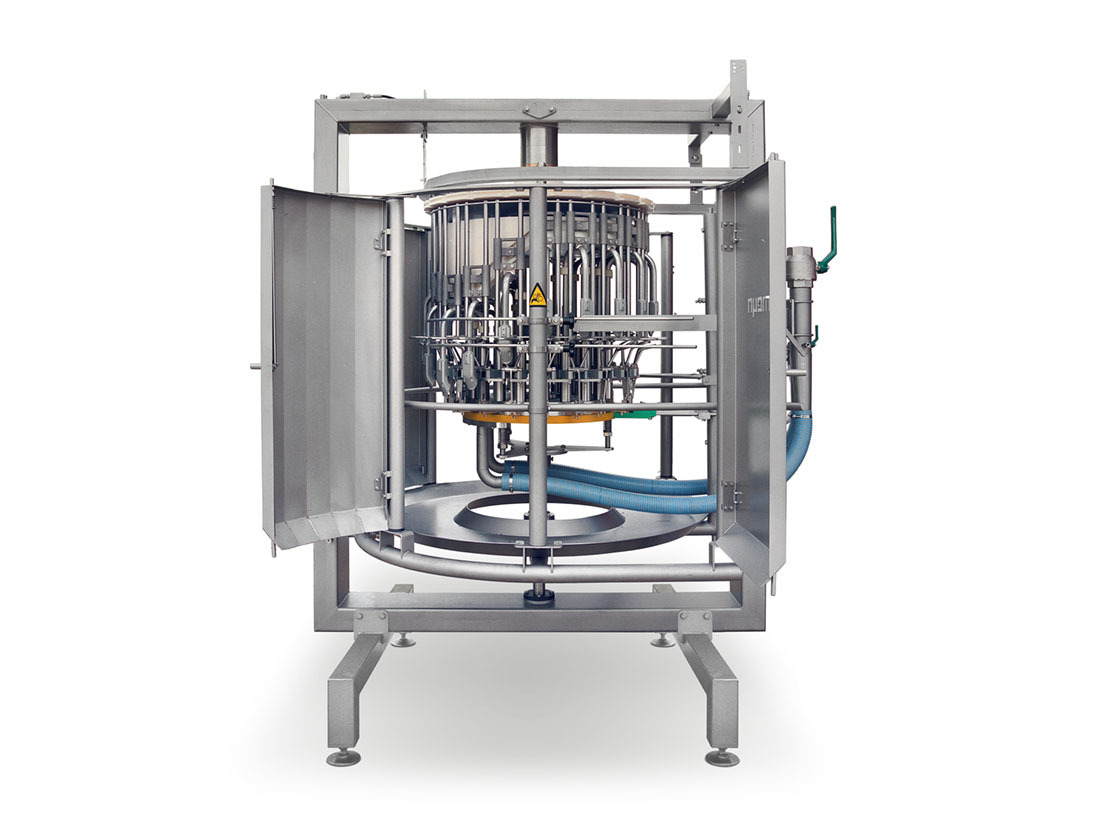

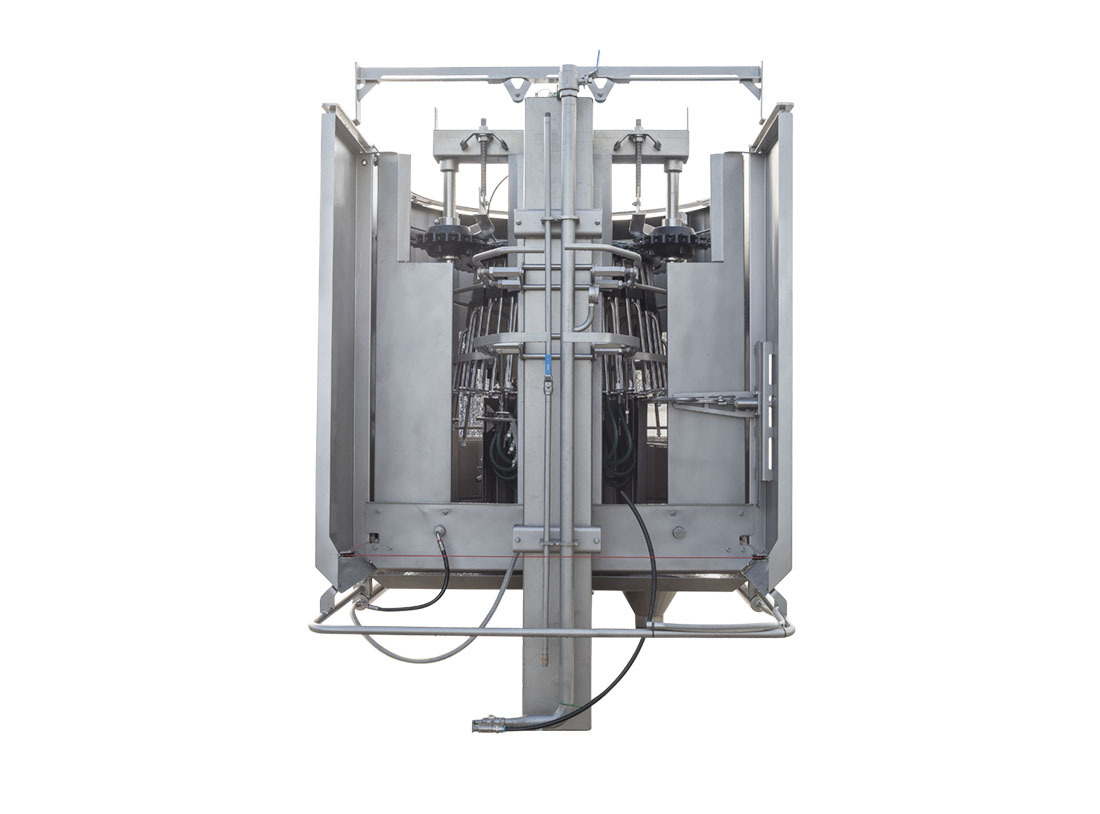

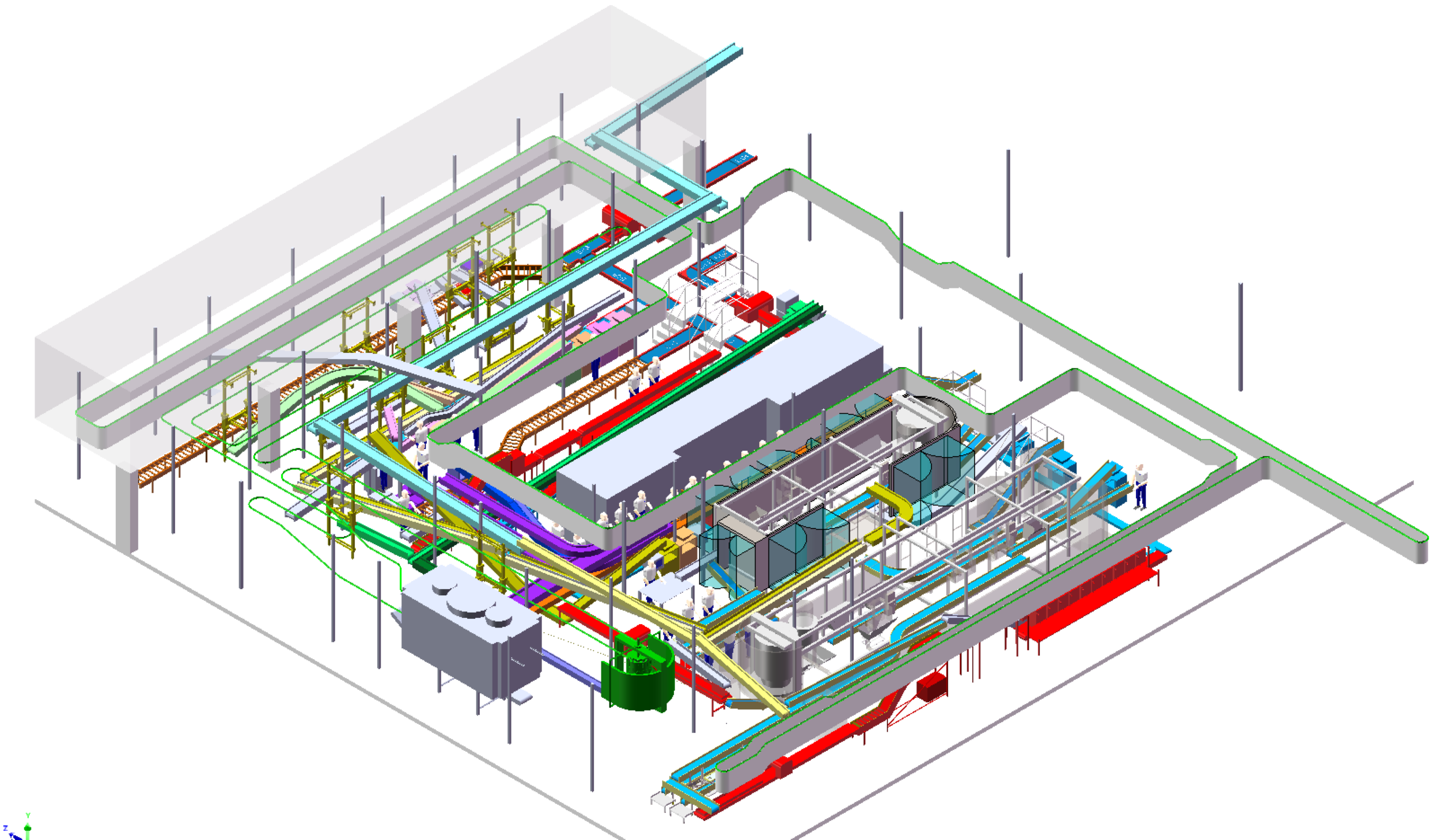

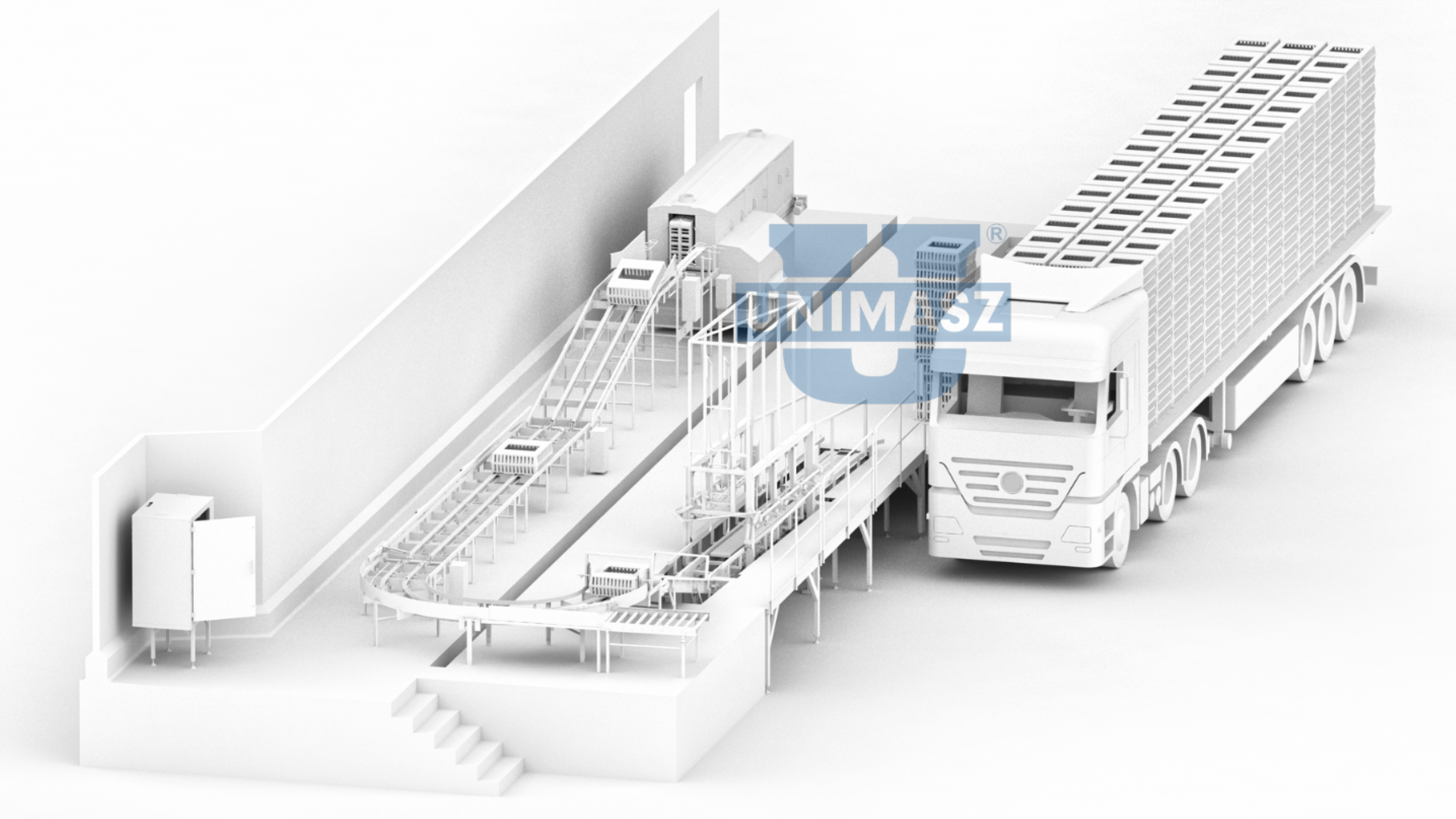

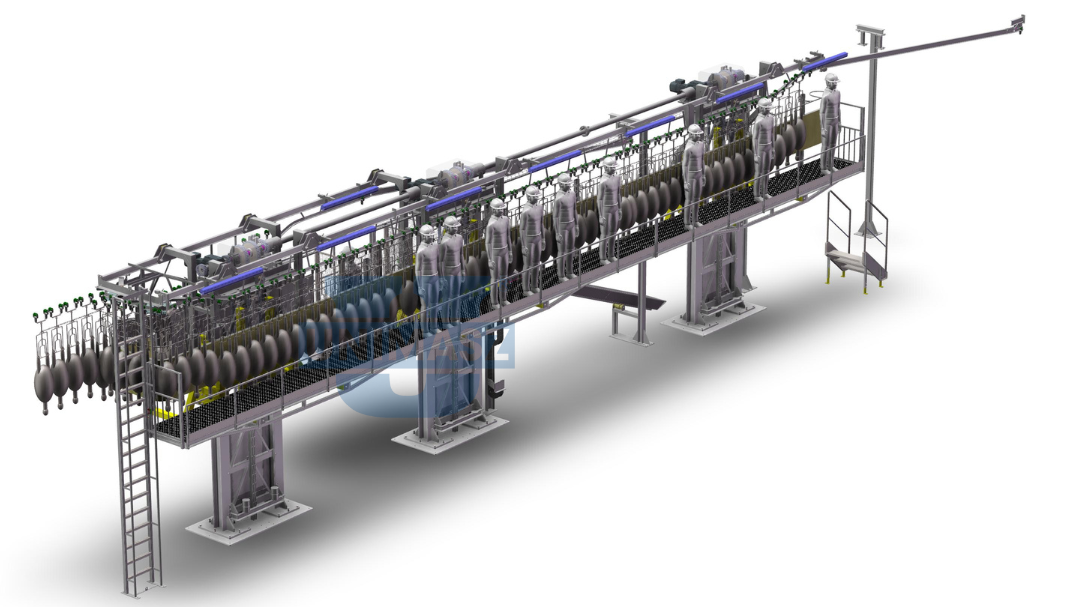

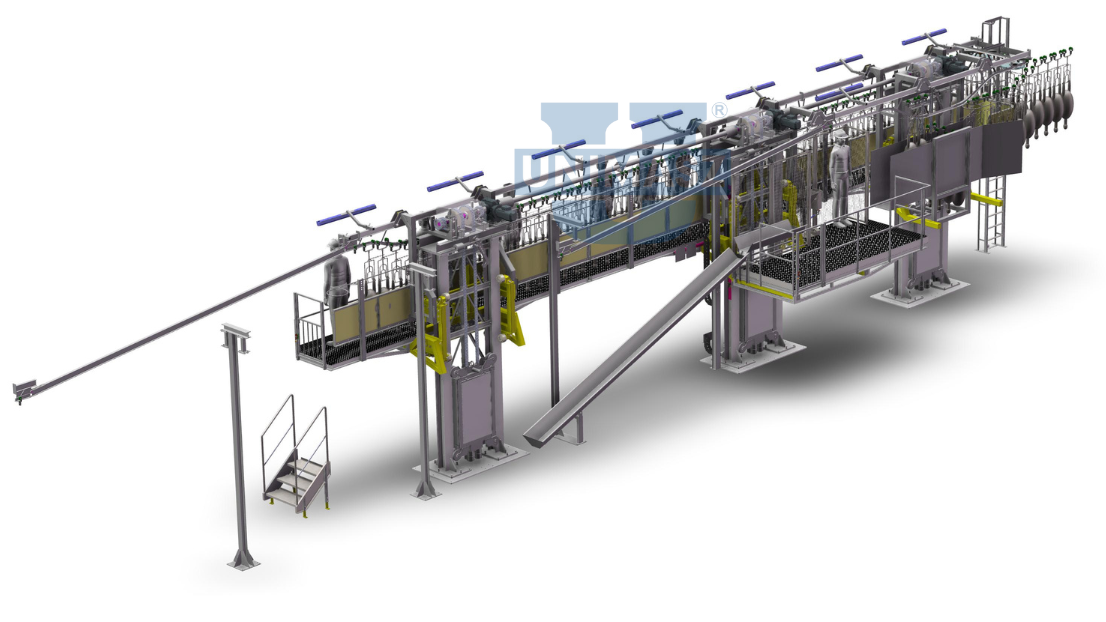

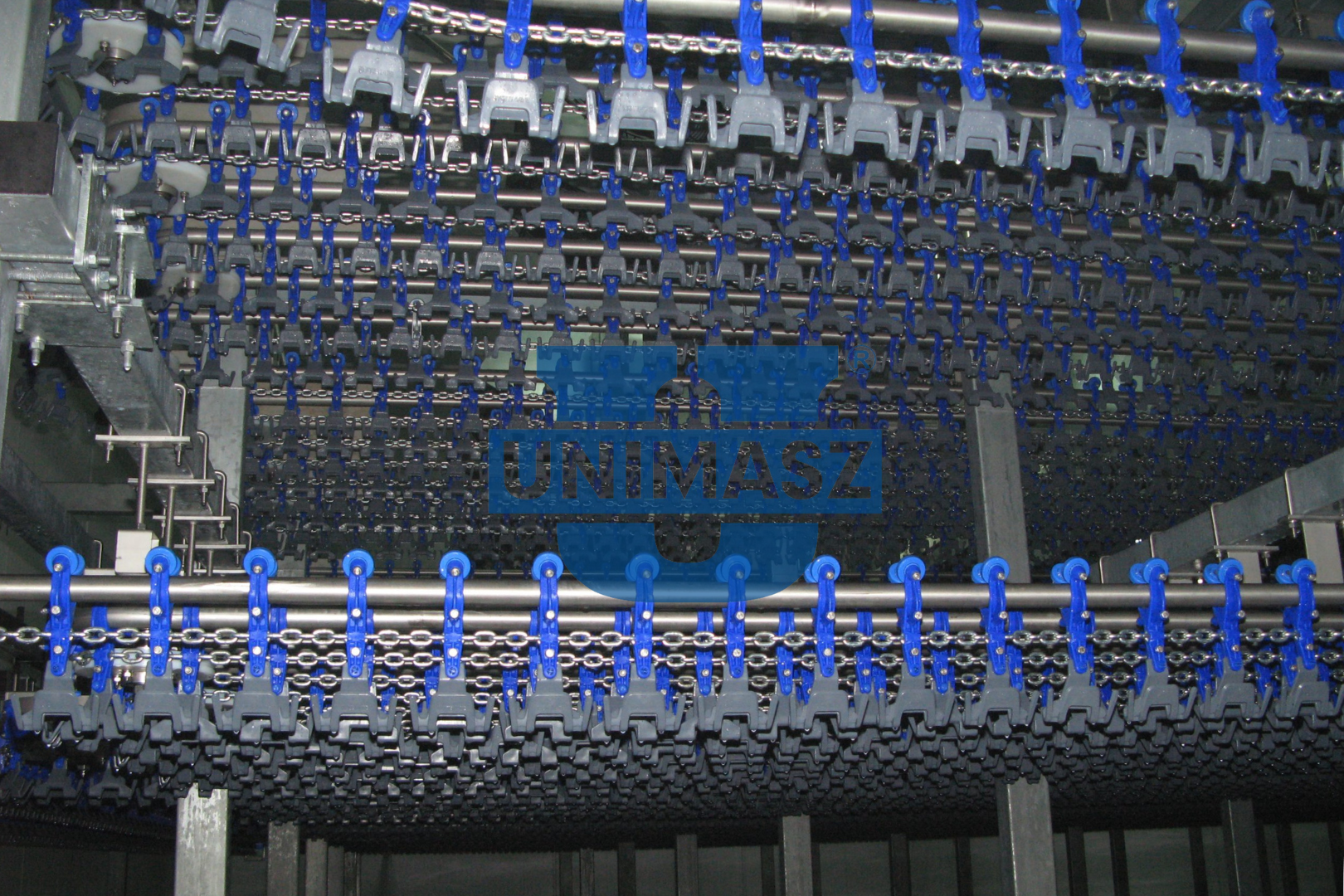

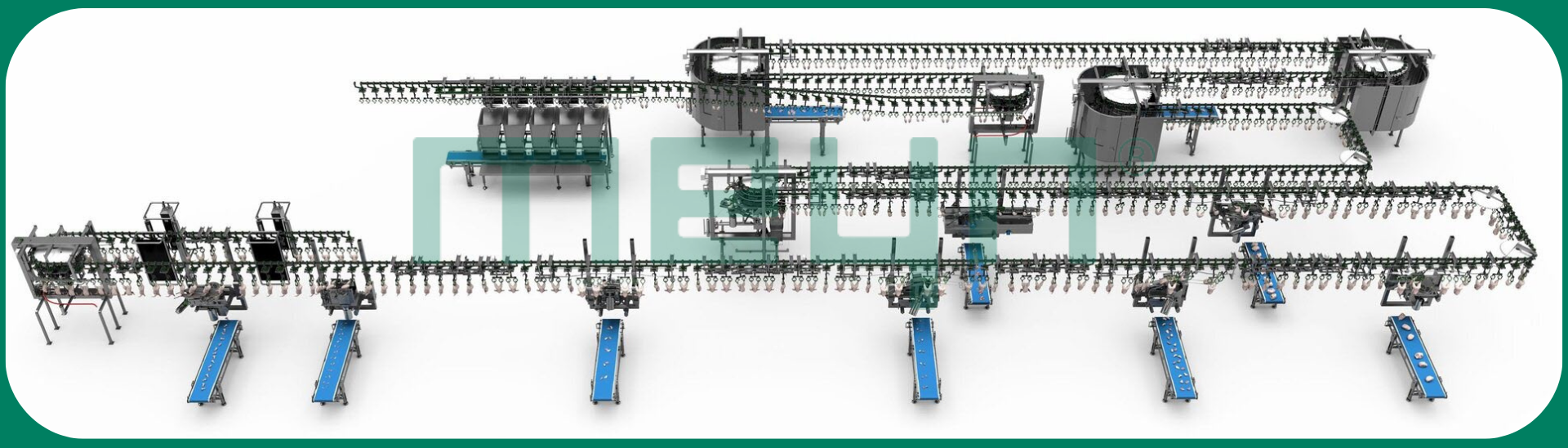

The evisceration line in poultry slaughterhouses is the section where the carcasses, after being stunned and plucked, are gutted to be prepared for cooling and cutting. Technological progress and rising labor costs are causing more and more slaughterhouses to modernize this section, and manufacturers of deboning machines are introducing further changes to reduce the number of jobs and improve the quality of deboning.