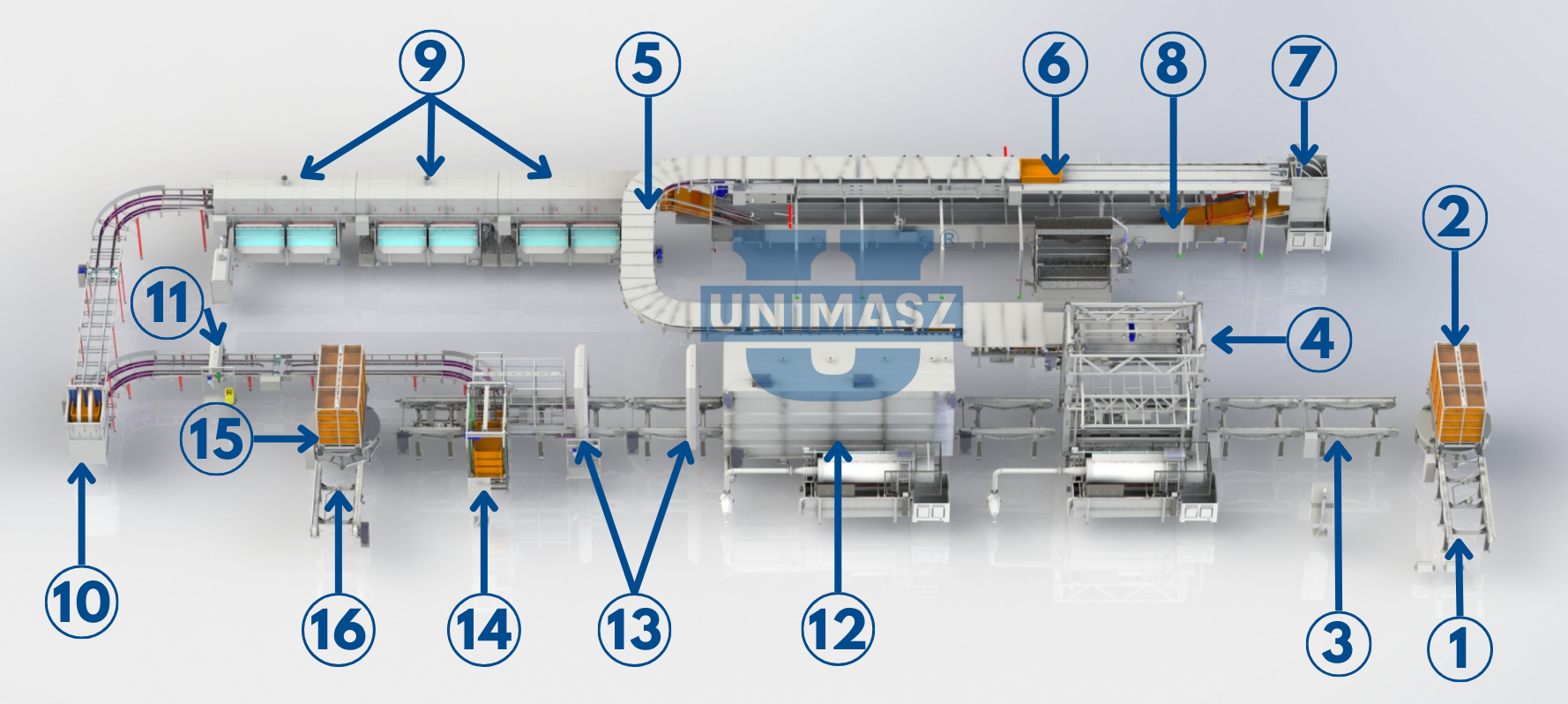

For drawer unloading systems, the proces starts with unloading a frame with drawers full of poultry from the truck.

| Max. capacity | – | 8 000 pcs./h |

| Served poultry types | – | chiken, duck, geese, hen |

| Compatible containers | – | 4 and 5 levels |

| Drawer capacity | – | 60 kg |

The line can be adapted to both four- and five-level containers with drawers transporting chickens, hens, ducks, and geese. One drawer can contain up to 60 kg of poultry.