The poultry feet chiller cools the temperature of poultry feet after the scalding and cleaning processes, to a value that allows them to be stored.

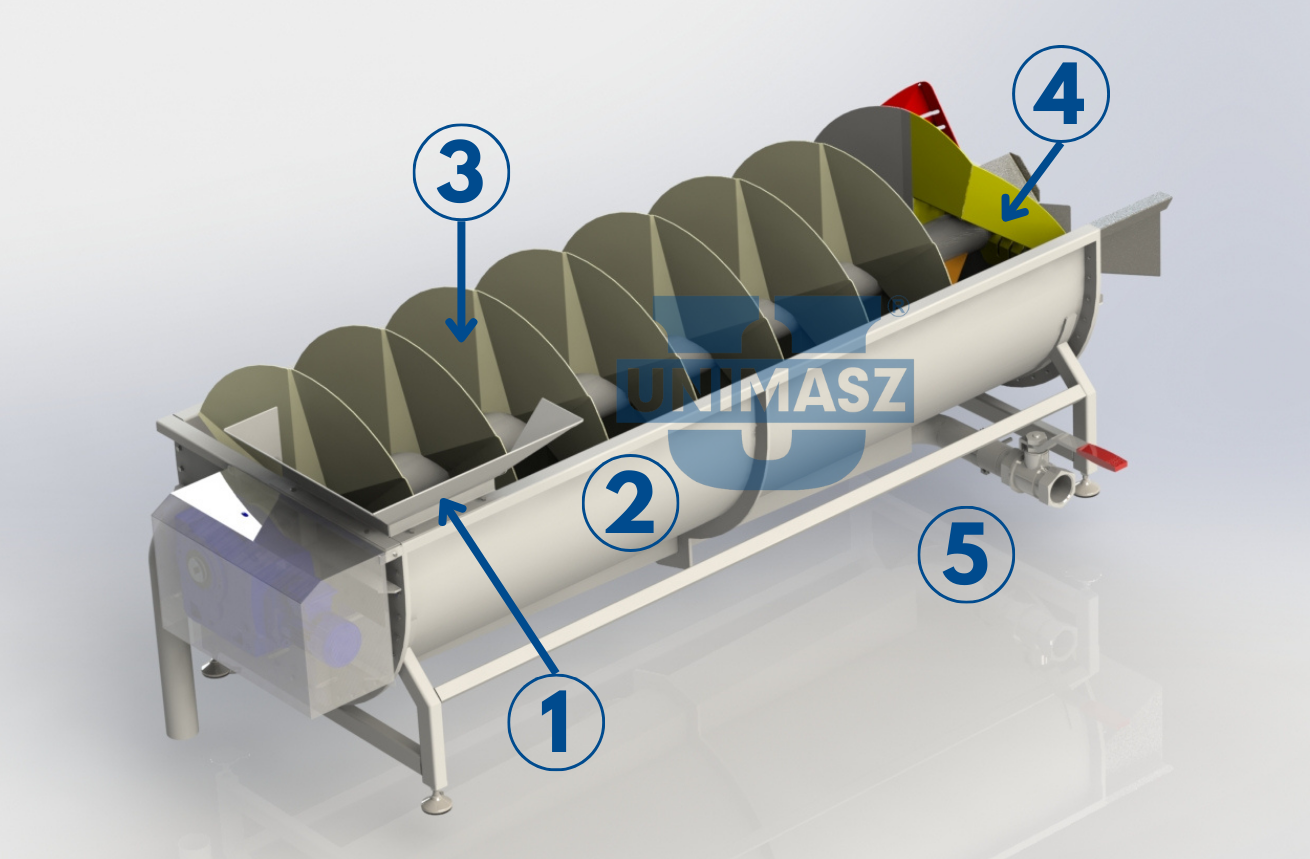

The feet fall into the chiller at the feed point, which is enclosed by a hopper (1) to prevent the feet from falling outside the trough (2).

The screw is terminated with a triple feather with a mesh of holes (4) to minimize damage to the feet and water loss.

To maintain a low temperature, we recommend continuous addition of cold water at the end of the process. At that time, the new water flows into the warmer area of the screw near the loading point.

| Capacity | – | max. 9000 pcs./h |

| Bath volume | – | 700 L |

| Screw working length | – | 2,4 m |

| Screw diameter | – | 0,85 m |

| Total height | – | 1,2 m |

| Drive power | – | 1 x 0,12kW |

Damage to feet– the triple feather of the screw at the end of the chiller improves the unloading of the feet by reducing the amount of feet pushed out at a time, preventing the chiller from clogging and crushing the feet.

Flexibility of parameters – the adjustable speed of rotation of the screw allows the chiller to be adjusted to the desired cooling parameters and performance.

Durability – the construction is made entirely of stainless steel, which is durable and resistant to the action of strong cleaning agents.

Our poultry feet chiller is a solution that meets strict EU standards and is a long-lasting and solid construction for many years.