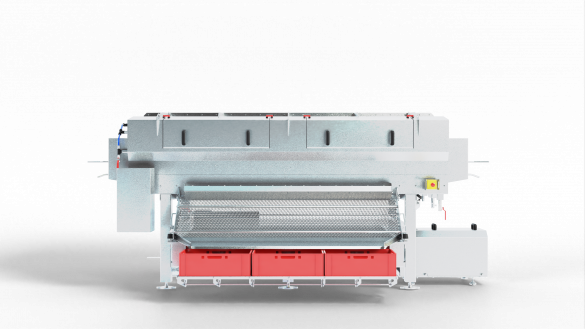

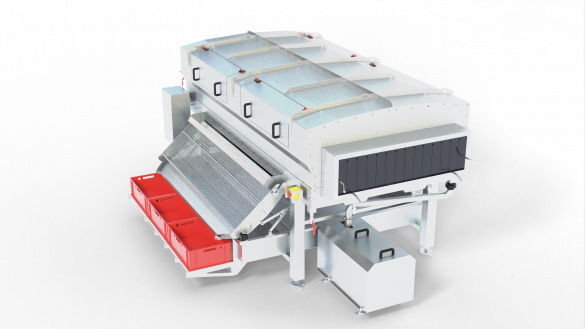

Description:

Washer of containers “drawers” is a specialized device for washing containers made of plastic.

Container transportation:

Loading into the machine is done manually or automatically from the pre-washing side and unloading from the opposite side, so the washer can be set up in line with a continuous transport system. Once the containers are positioned in the loading section, they are automatically moved along the pre-wash, main wash and final rinse sections.

Construction:

The enclosed design provides complete safety for workers when the machine is operational. In addition, the use of tunnel design allows for the seamless positioning of the transverse wall separating the clean zone from the dirty zone. Construction from acid-resistant steel enables maintenance of strong cleaning agents for the best hygiene. In addition, an easy-to-read control panel allows the operator of the washer to fully control the washing process. In our equipment we use proven components of reputable companies.