is the ideal apples unloading system on a mass scale!

It is designed for efficient and fast unloading of apples from trailers and crates.

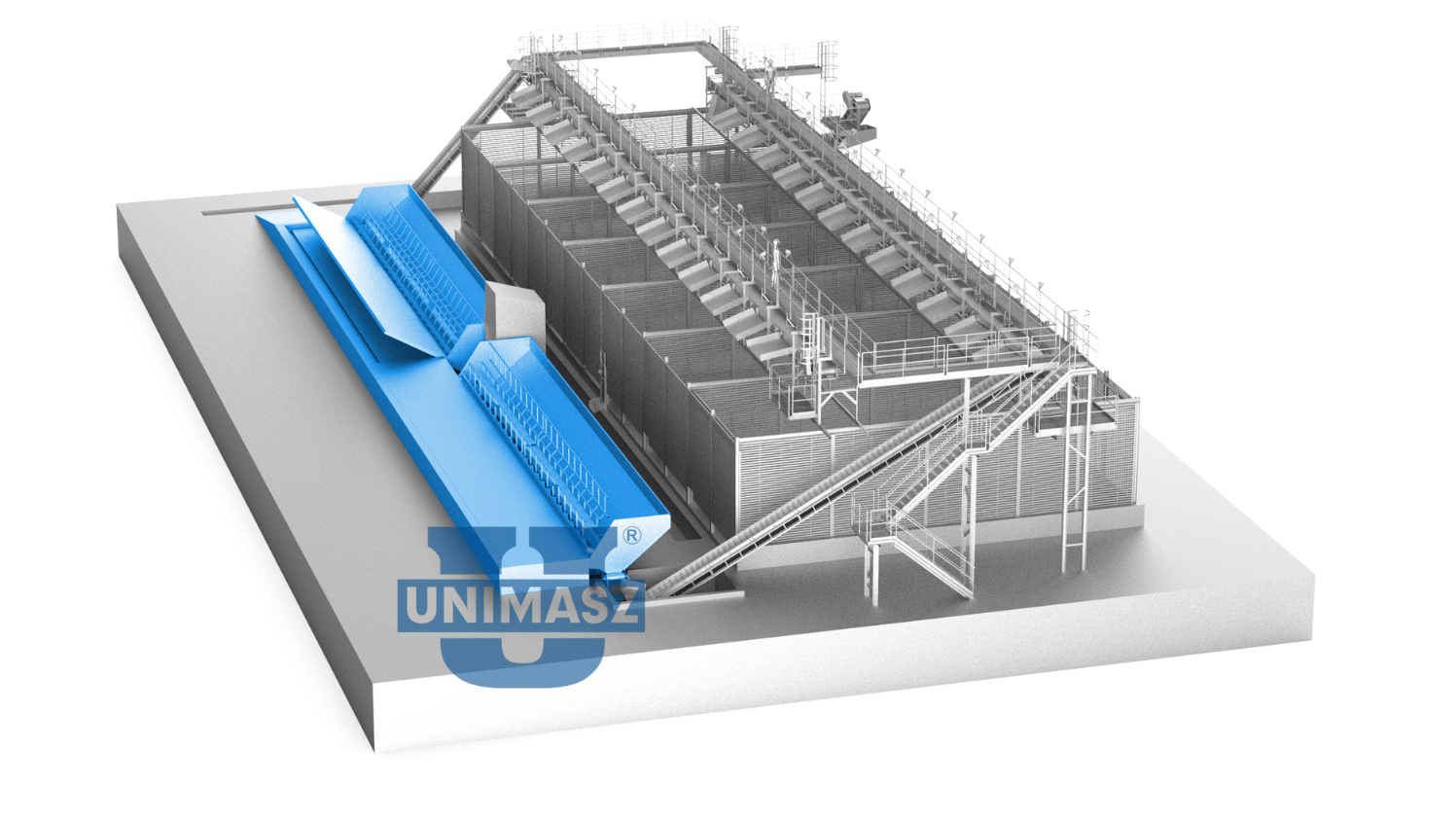

Upon arrival, the driver can see the hoppers on the left side of the tipper.

The tipper is equipped with

The tipper lifts the trailer by up to 30° to completely unload the apples.

Unloading is done from the semi-trailer into a chute basket with a conveyor belt underneath the basket.

The hopper is equipped with a reinforced bumper to help sustain huge loads.

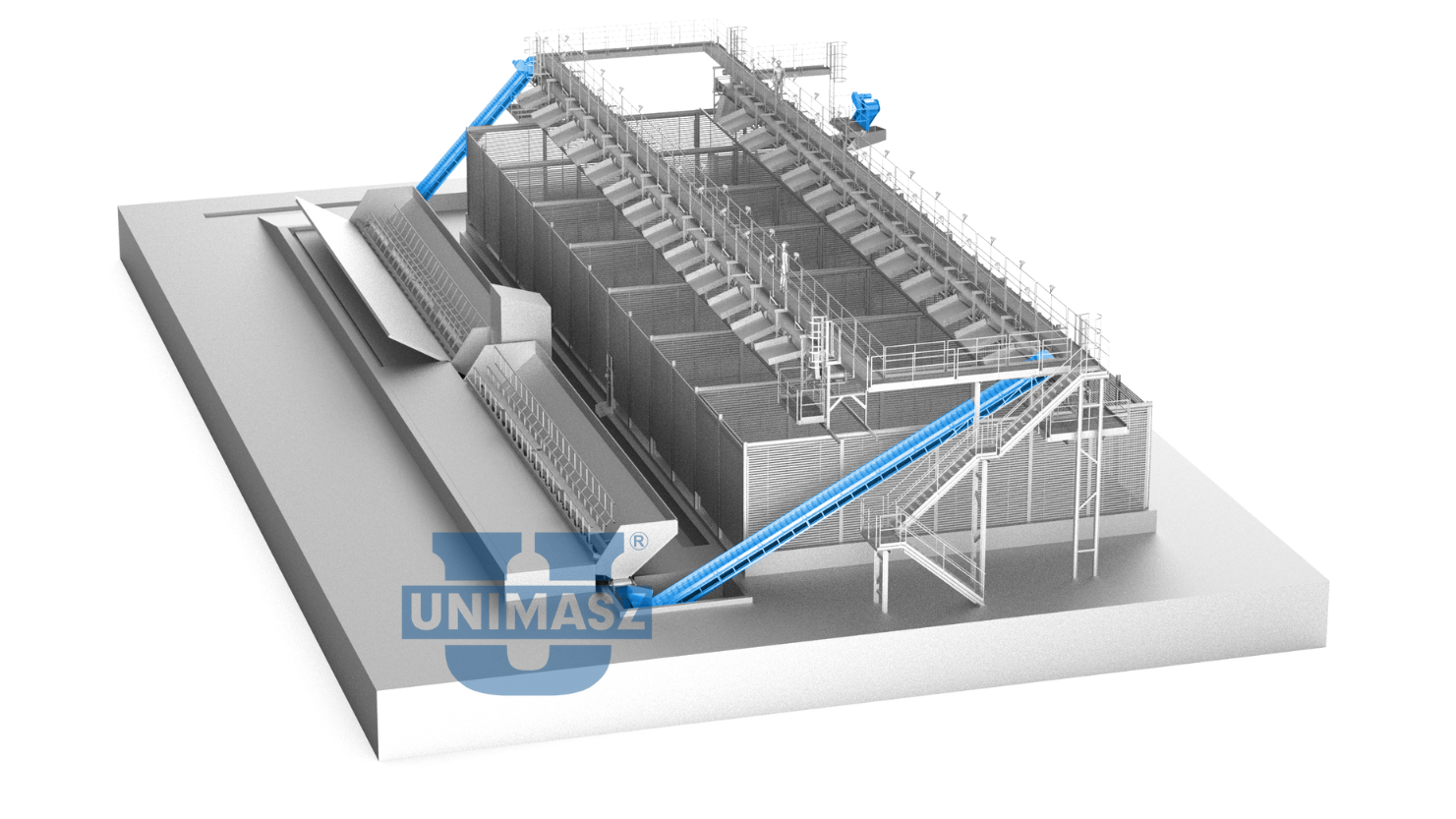

The conveyor with the hopper transports the goods to an inclined conveyor and then to a separating conveyor placed along the silo.

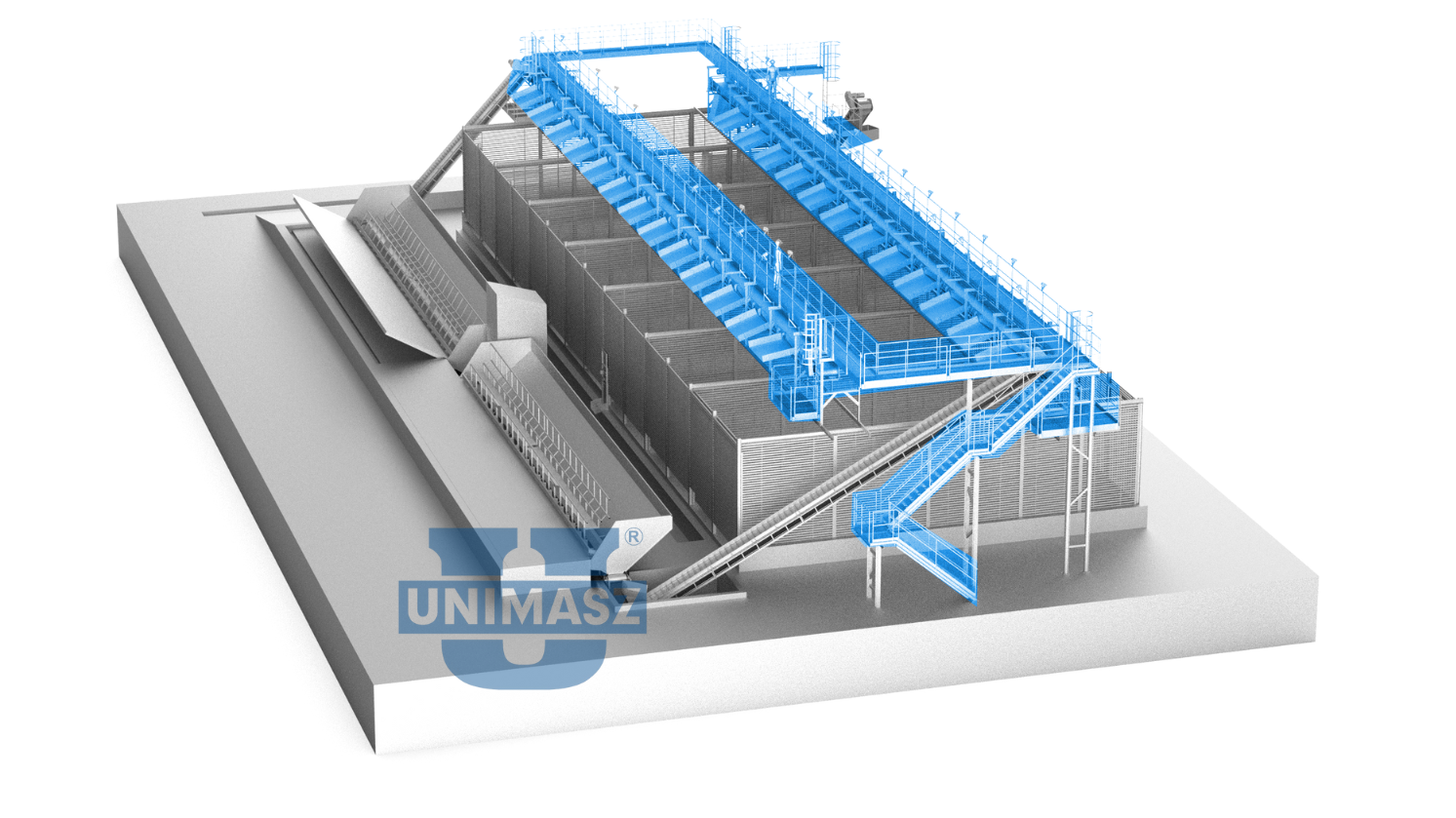

The distribution conveyor is equipped with movable borts and chutes (angle and length adjustment) to allow the transport of goods to individual silo boxes.

An employee operating the conveyor manually opens the individual moving borts and adjusts the extension and angle of the chute during unloading to fill the box completely.

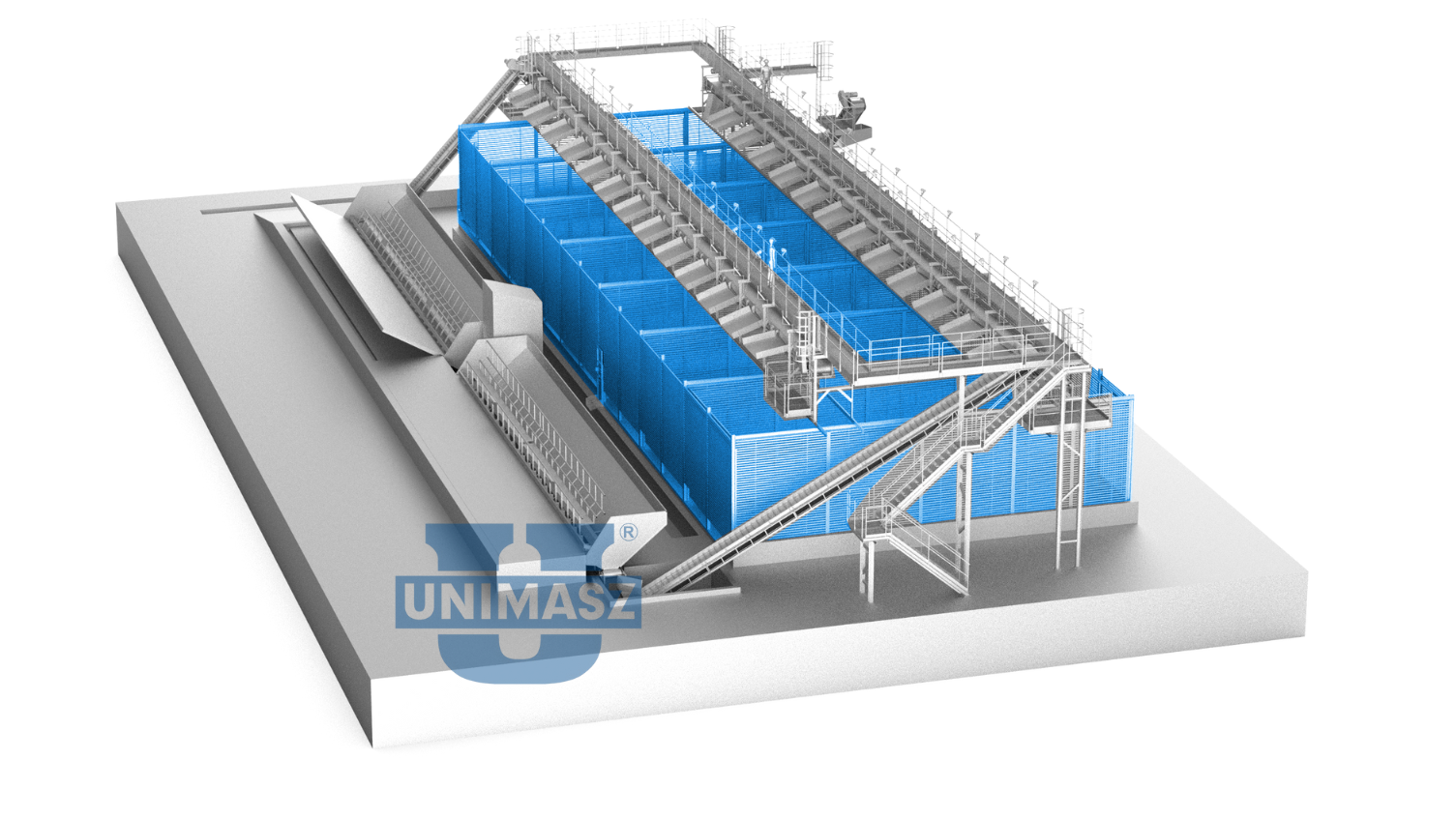

The box is emptied by raising the drain sluice upward and allowing water to drain the apples into the canal.

Once the box is emptied, the drain sluice is closed and the box is ready to receive the next delivery of apples.

| Capacity: | about 100t/h | |

| Bunker capacity: | about 2500m3 | |

| Methods of unloading: | from side using tipper | from the back with box pallets |

| Capacity of the chute basket: | about 45m3 | |

| Power demand: | 70kW | |

| Water demand to float 1 box: | about 350m3/h | water flows in closed loop and is filtered |

| Unloading vehicles – different types, height from the level of the tipper to the floor: | from 1m –to 1,3m, height borts 0,4m-0,8m |